Load Bearing: More Than 30 Tons

Warranty: 18 Months

Body material: GB Cast Aluminium alloy

Power supply: USA Brand Flexible High Efficient Solar Panel (2.5V/0.38W)

Visual distance: > 800m

Working Mode: Flashing or Constant

Waterproof: IP68

Shank: With shank or Without shank

Solar Stud For Road R1 Features:

•High brightness America brand led light with 100000 hours of working time.

•USA brand solar panel. 22% high conversion rate. Fast charge rate.

•Japan brand casting Al material. Solar Stud For Road bears more pressure.

•Most quality Epoxy resin glue to fix the Solar Stud For Road, making sure of solar power charge.

•Philips PC board, safe and stable. Long-time warranty for Solar Stud For Road.

•The leader of Solar Stud For Road. Load capacity:>30T(can be installed in the middle of the road)

Aluminum Solar Stud For Road Parameters:

| Body material: | GB Cast Aluminium alloy |

| Power supply: | USA Brand Flexible High Efficient Solar Panel (2.5V/0.38W) |

| Battery: | NI-MH 1.2V/600mah(high-temperature resistance, made in China); Lithium Battery 3.2V/500MA(made in Japan); Supercapacitor 2.3V/120F(made in Korea) |

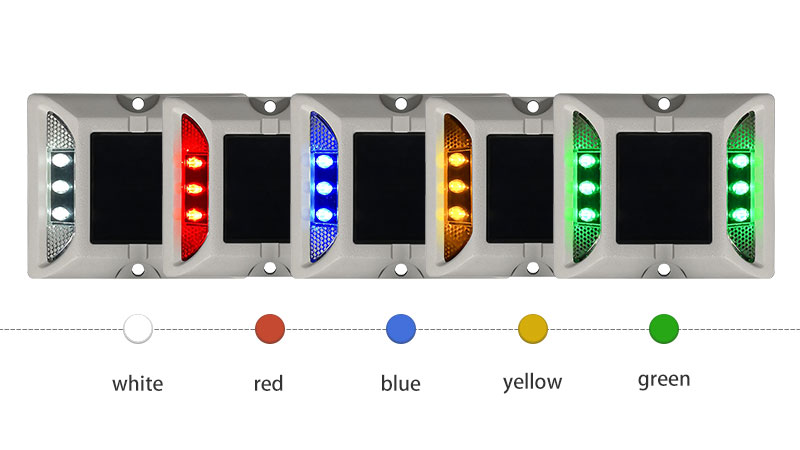

| LED: | Ultra-bright diameter 5mm(4pcs or 6pcs) |

| Shank: | With shank or Without shank |

| Working model: | Blinking or Constant(charging at daytime and working automatically at night) |

| Load Bearing: | More Than 30 Tons |

| Visual distance: | > 800m |

| Size: | L125*W107*H25+55mm (L4.92″*W4.21″*H0.98″+2.17″) |

| Package: | (without spike): 2pcs/box; 60pcs/ctn; Weight: 28kgs; Carton size: 67.5*28*20cm (2pcs/box; 60pcs/ctn; Weight: 61.73bs; Carton size: 26.57″*11.02″*7.87″) (with spike):1pcs/box; 45pcs/ctn; Weight: 30kgs; Carton size: 66.5*44*28cm (1pcs/box; 45pcs/ctn; Weight: 66.13bs; Carton size: 26.18″*17.32″*11.02″) |

Aluminum Solar Stud For Road R1 Application of Aluminum solar studs R1:

♥Schools and hospitals

♥Highways

♥High traffic areas

♥Walking paths

♥Transit stations

♥Parks and campuses

♥Urban Road

How to install Aluminum Solar Stud For Road with shank R1:

1. Carefully mark the distance between the placement of the Solar Stud For Road. To prevent adverse effects on the ground, use appropriate tools, such as core drills, which have a diameter of 35mm and a depth of 55mm.

2. Remove all debris from the mounting hole.

3. Pour epoxy resin into the hole according to the manufacturer’s instructions.

Make sure that the mounting holes are straight. Make sure that the mounting hole is large enough to allow epoxy resin to surround the Solar Stud For Road.

4. Adjust the lighting surface of the Solar Stud For Road to the desired viewing angle.

5. Make sure that the epoxy resin adheres evenly to the mounting hole and the Solar Stud For Road. Make sure that the bottom of the Solar Stud For Road is securely mounted on the mounting surface to ensure that zero “surface floating” occurs. (Space between the installation sign and the bottom of the Solar Stud For Road).

6. After curing the LED Solar Stud For Road for 6-8 hours, remove the installation of the isolation facility.